Lost wax casting bronze, Lost wax casting technique

What's lost wax casting?

Lost wax casting technique is an ancient process, dating back at least 5000 years, used to obtain bronze objects.

All process steps of lost wax casting reflect this ancient method even if lost wax casting technique and raw stuff keep on changing.

Advantages of lost wax method

Although many artistic foundries use lost wax casting technique because highly accurate in faithfully reproducing sculptures details, this not means this technique does not require special skill and knowledge in this area. As a matter of fact lost wax casting is very sophisticated and it's a time-consuming process; this is the reason why many sculptors cooperate with BMN ARTE to realize their works relying on qualified staff.

Calc: first step of lost wax casting

First step of lost wax casting is the calc, a sort of imprint of the original model which will be produced by casting process of either metal or alloy chosen.

BMN ARTE produce the calc using either silicone or plaster. Producing moulds for statues is very important for the work success. Our artistic foundry has an excellent experience in this field.

WAX: the second step of lost wax casting

Second step consists in reproducing into wax the original model using previously produced calc and after various procedeures wax work is obtained.

During this same step we move on to wax retouching.

Wax retouching:: the third step of lost wax casting

Accurate retouching and finishing are needed to get a wax model closest to the original one with the purpose of obtaining an impeccable result. This is the step coming before lost wax casting.

Casting: fourth step of lost wax casting

During this phase casting prameters are set up once alloy or metal are ready to start casting , using moulding box. This phase has to be under careful supervision of an experienced master.

Once casting is over, moulds have to rest where they are for some days in order to avoid either sharp shrinkage or dangerous internal strain could compromise good result of casting and long bronze durability.

Chiseling: fifth step of lost wax casting

Using specific tools chiseler retouches work, removing possible chemical residues, highlighting details and refining contours to obtain a perfect work of art.

Bronze statues and all bronze artworks (as well as those produced with all alloys/metals) are then coated.

Coating: sixth step of lost wax casting

Out of casting bronze sculpture has eterogeneous look; as this stage a specialist applies patina produced with chemicals, giving to work the required colour and showing the unique features of the work iteself.

As to bronze objects, for instance, they usually are coated by a patina in various colours from a green tone to a brown slightly reddish shade; customers almost never choose bronze classic yellow gold colour.

Packaging: seventh step of lost wax casting

BMN Arte provide turnkey service that is "lost wax casting sculpture for you". We not only produce artworks and sculptures, we also provide their packaging and relevant adornments in order to show the value of our works making them suitable for the use you wish.

NEWS / EVENTS

San Pietro e San Paolo in bronzo fuso a cera persa tratti dalla Basilica di San Zeno

June 16th, 202229 giugno: festa liturgica in onore del martirio a Roma dei due apostoli San Pietro e Paolo. La celebrazione è di antica origine cristiana, la data selezionata è l...

Read More

Virtù tratte dalla Basilica di San Zeno di Verona in bronzo fuso a cera persa

June 15th, 2022"Giustizia" e "Prudenza" sono due delle quattro Virtù tratte dal portale bronzeo della Basilica di San Zeno, patrono di Verona. La prima indica l...

Read More

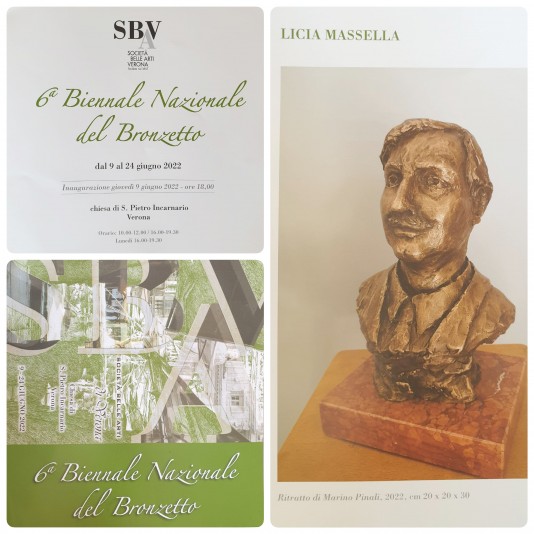

VI Biennale Nazionale del bronzetto a Verona

June 13th, 2022Anche la nostra fonderia artistica BMN Arte è presente alla sesta edizione della Biennale del Bronzetto, organizzata dalla SBAV a Verona. Con il ritratto di Marino Pinali...

Read More